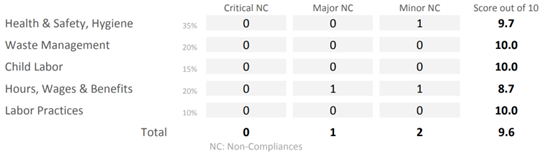

Factory Overall Score :9.6

Audit Rating green Approved

Important Remarks

Positive Remarks

1:

1), Most documents such as building structure safety certificate, fire safety certificate, risk analysis, fire drill records and photos, training records, occupational hazard factor testing report, occupational health check report and etc were provided for review.

2), All fire equipment such as fire extinguishers, fire hydrant, fire hoses, fire alarm, emergency light and exit sign, evacuation plan and etc were installed in the factory and maintained properly.

3), Cargo lift inspection report was provided for review. There was adequate qualified electrician to deal with the electricity in the factory. And the certificates for special equipment and electrician were provided for review during the audit date.

4), 14 workers trained on first aid, and the certificate was provided for review.

5), Drinking water with testing report was provided for employees for free of charge.

6), There was an appointed are to store chemicals secondary containment and eye wash facility was provided.

7), Dormitory, kitchen and canteen were maintained well.

2.

1), All documents such as Environmental Impact Assessment and related approval, pollutant discharge permit, air emission and noise level testing report, acceptance approval and etc were provided for review.

2), Industrial wastewater was transferred to the qualified vendor.

3), Solid waste and hazardous waste were controlled and managed properly.

4), Hazardous waste was transferred to a qualified vendor by the factory.

3.

1), All employees’ personal files with ID cards copies were provided for review. No child labor and young workers were identified during this factory visit.

2), The factory signed labor contracts with all employees and gave a copy to each employee.

4.

1), All employees’ wages and attendance records of past 12 months (from Oct-2019 to Sep-2020) were provided for review, all workers had one day off per seven days; the minimum wages of all workers met local minimum wage, and the overtime wages were paid as per legal requirements.

2), The factory used electronic attendance system (fingerprinting system) to record workers’ working times.

3), Benefits such annual leave and statutory holiday were provided for all employees.

4), Wages were paid before the end of the following month by bank transfer.

5.

1), No violation on forced labor, discrimination, entitlement to work and immigration and etc was identified. While related procedure/policy (such as forced labor, anti-discrimination policy, disciplinary rule, entitlement to work and immigration and etc) were established.

2), No trade union was found in the factory, 6 worker representatives were selected by the factory. Sufficient channels (such as suggestion boxes, etc) were provided to workers to report their concerns.

3), Employees were employed based on recognized and documented employment relationships. No subcontractor, agency or dispatched worker used by the factory. Assessment had been conducted to its suppliers.

1st follow up audit on 29-May-2021

All employees’ wages and attendance records of past 4 months (from Dec-2020 to Mar-2021) were provided for review, all workers had one day off per seven days; the minimum wages of all workers met local minimum wage, and the overtime wages were paid as per legal requirements.

2), The factory used electronic attendance system (fingerprinting system) to record workers’ working times.

3), Benefits such annual leave and statutory holiday were provided for all employees.

4), Wages were paid before the end of the following month by bank transfer. Areas of Improvement

1. 1), No adequate occupational health check was provided to relevant workers.

2), Kitchen staff did not wear cloth, hat and mask.

3), No building safety structure certificate was available for the dormitory building and office building.

4), The was fire-fighting equipment was blocked.

5), Ladder had no handrail installed.

2. 1), The factory had not separated recyclable from non-recyclable wastes.

2), Hazardous waste was stored with non-hazardous waste.

3), Wastewater and air emission were not established with inventory.

3. N/A

4. 1), The factory did not ensure overtime hours comply with legal requirements and weekly working hours within 60 hours/week.

2), Insufficient social insurance participated.

Corrected:

1), Dequate occupational health check was provided to relevant workers.

2), Kitchen staff wore cloth, hat and mask while operating.

3), Building safety structure certificate was available for the dormitory building and office building.

4), No fire-fighting equipment was obstructed.

Not corrected:

1), Ladder had no handrail installed.

2. Corrected: 1), Hazardous waste was stored with non-hazardous waste separately.

3), Wastewater and air emission were established with inventories.

Not corrected:

1), The factory had not separated recyclable from non-recyclable wastes.

About Factory

- Health & Safety, Hygiene

Is a risk analysis conducted to identify the risks associated with production and is this risk analysis reviewed regularly and updated when necessary?

The factory had conducted a risk analysis to identify the

risks associated with production, and the records were

provided for review.

Is there a senior management representative for Health & Safety?

There was a senior management representative for Health & Safety/Mr. Huang Liping. Safety officer certificate was available for review.

Does the factory arrange health and safety training for new workers and for everyone who changes working roles?

The factory arranged health and safety training for new workers within three days while recruited.

Does the factory have a working environment that is wellventilated, comfortable temperature, decent lighting,

clean, tidy and enough room for each worker? If there are

any possible issues that would impact the health of the

worker, please give details.

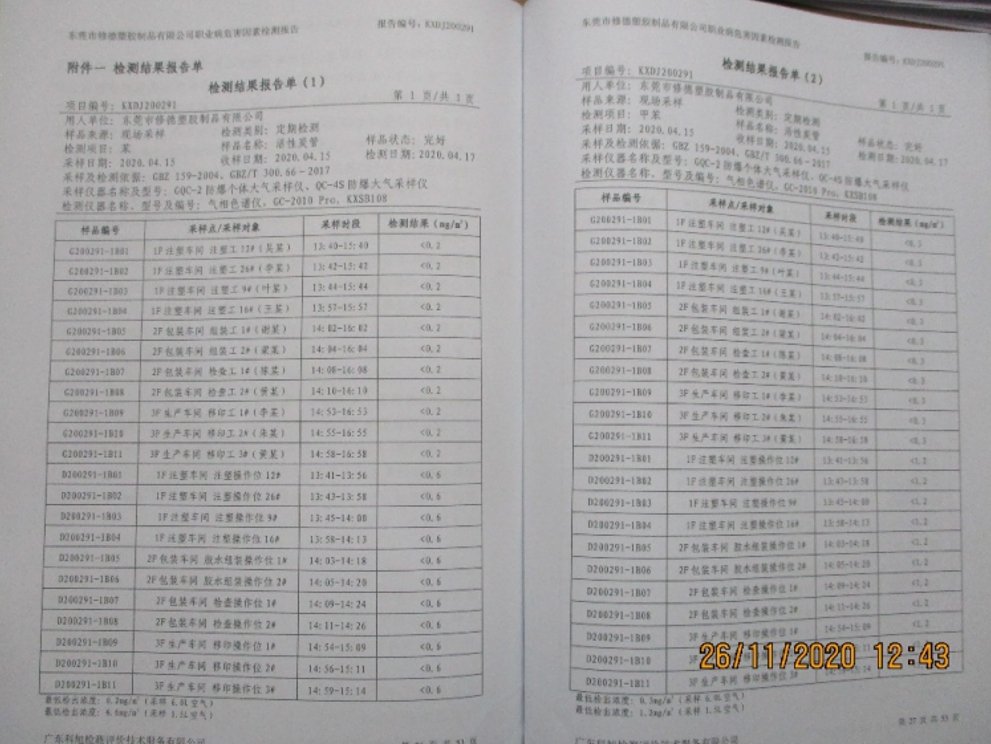

The factory had a working environment that is wellventilated, comfortable temperature, decent lighting,

clean and enough room for each worker, and

occupational hazard factor report and occupational

health check report was provided for review.

Are all serious work-related accidents reported and recorded and corrective actions taken to prevent recurrence of workrelated accidents?

There was a work-related accidents procedure in place and work-related injury records were available. And based on document review and workers interview, no injury was occurred in the past year

Is appropriate and adequately maintained personal protective equipment (PPE) provided by the factory?

Based on factory tour it was noted that Personal Protective Equipment (PPE) such as earplugs and masks had been provided by the factory for free of charge.

Have workers been trained in the use of PPE and are using provided equipment correctly?

The workers had been trained in the use of PPE. And proper PPE such as earplug were provided for terminal compression operators for free of charge.

Do workers have access to an adequate amount of fresh drinking water?

The factory had provided the employees with adequate drinking water, the test report was provided for review

Is there an adequate number of first aid kits?

The factory had installed first aid kit at each work floors; there was total 9 first aid kit in the facility workshops.

Are first aid kits easily accessible and clearly marked and the content within the expiry date, applicable and replaced when used?

First aid kits were easily accessible and clearly marked. However, during site tour, it was noted that no adequate first aid suppliers was provided to the first aid box located at the 1st production floor.

Are adequate workers trained on first aid?

The factory had arranged 14 workers to train first aid, the certificate was issued.

Are lavatory and or washroom facilities, clean, well maintained, adequate in number, separated by sex, and with relevant privacy?

The lavatory and washrooms were found well clean, maintained, adequate in number, separated by sex, and with relevant privacy. Remark: Total 17 toilets for males, 23 toilets for females.

Are legal construction certificates (building structure) available?

The Building Structure Safety Certificate for the production building was provided for review during the audit.

Are all site buildings, including dormitories maintained in good condition without posing a threat to the health of workers?

The factory building was maintained in good condition without posing a threat to the health of workers.

Does the factory have adequate unblocked fire exits for every factory workshop/floor ?

At least 2 fire exits with unblocked or unlocked were available for every workshop and warehouse.

Has the factory been certified by the local fire bureau, and made efforts to comply with recommendations from audits?

The factory had obtained Fire Safety Certificate from local fire bureau for the production building in the factory.

Are there an adequate number of fire extinguishers and or other fire extinguishing systems in each building (including the dormitories)?

here are sufficient fire extinguishers and fire hoses for all production areas. The total amount of fire extinguishers was 68 fire hydrant was 19 and fire alarm was 19.

Are all fire extinguishing systems (including fire hoses) inspected, maintained properly and ready to use at all times?

The facility has periodically (monthly) maintained the fire extinguishers, fire hydrants and fire alarm. And the maintenance records were posted nearby and the latest checking was on 2-Nov-2020.

Are fire drills conducted regularly?

The facility has conducted fire drill twice per year and the latest two fire drills were conducted on 28-Apr-2020 and 28-Oct-2020.

Are there fire alarms on each floor and adequate emergency lighting above exits and in working order?

Based on site observation, adequate fire alarm was installed at each production floor, and emergency lighting and exit sign were installed above all exits.

Are there fire/evacuation procedures in place with relevant evacuation plans posted in every workshop?

Evacuation map was posted on the work floors. Evacuation line was also clearly marked on each work floors.

Are smoke detectors/sprinklers installed in all workshops/warehouses?

Sprinkler system were installed at the warehouse/workshops.

Does the factory have appropriate maintenance/inspections for boilers, elevators, pressure vessels and other equipment per local regulation?

Only one of cargo lift was used in the factory, the latest annual inspection report was provided for review. No any other special equipment used in the factory.

Are adequate guarding or devices installed for moving/rotating parts of machine, pulleys and belts or any other dangerous parts of machines?

Adequate guarding or devices were installed for moving/rotating parts of the production machines. However, during site tour, it was noted that one ladder with about 1.5 meter high located at the logistics room had no handrail installed.

Are all electricians, welding operators and forklift drivers and other employees who operate special equipment trained and qualified per local regulations?

Employees who operated special equipment trained and obtained operation certificates. There was one qualified electrician to deal with the electricity in the factory. And the certificate was provided for review during the audit date.

Are all electrical wires in the facility adequately protected?

During factory tour, auditor found that all electrical wires were adequately protected by tubes and electrical boxes were installed with protective cover. However, during site tour, it was noted that employee switched on the power privately in the dormitory, there was maybe an electrical safety risk there.

Are there appropriate warning signs and written instructions for the operators of machinery?

All the electric cables in the facility were properly grounded and fixed in a secure manner

Do operators of machinery get training about safety regulations and operating procedures?

Workers operate machines are provided with training safety regulations and operating procedures.

Are hazardous materials / chemicals properly stored, with relevant container and secondary container?

Based on site observation, separated area was used for chemicals storing.

Does the factory have MSDS and warning / “No Smoking” signs for each chemical products?

Chemical MSDS was available for chemicals in the factory.

Are these materials only accessible to competent employees ?

The chemicals were controlled by the pointed warehouse keeper.

Are the designated employees properly trained for the handling of these hazardous materials?

The chemical use training was conducted at least once per year, and related training records were provided for review.

- Waste Management

Does factory have a valid Environmental Impact Assessment (where applicable)?

The factory had provided environmental impact register report form during the audit, and the factory had obtained environmental impact report approval issued by local environmental authority.

Does factory have a valid Approval Report of Environmental Impact Assessment, or relevant legal document to start operations?

The factory had provided environmental impact register form during the audit, and the factory had obtained environmental impact report approval and acceptance report approval of environmental protection facilities of construction project issued by local environmental authority.

Does factory maintain a valid Pollutant Discharge Permit or equivalent, where applicable?

Pollutant Discharge Permit was available in the factory

Does factory inventory all solid wastes, including kind, sources, and quantities?

The factory had established inventory for all solid wastes, including kind, sources, and quantities.

Does factory adequately separate recyclable from nonrecyclable wastes in workshops/warehouses?

The factory had not separated recyclable from nonrecyclable wastes.

Can factory prove that they have taken actions to reduce/recycle/re-use solid wastes as much as possible?

The factory has reduce/recycle/re-use solid wastes in the factory.

Does factory inventory all hazardous wastes, including kind, sources, and quantities?

The factory had established effective hazardous wastes inventory.

Does factory store hazardous wastes in a relevant way, closed, with control access and ensure it cannot spill?

There was a designed area for hazardous waste storing with a relevant way, closed, control access and not spilling. However, during site tour, it was noted part of hazardous waste such as empty containers were stored with non-hazardous waste.

Is factory able to prove that hazardous wastes are transferred to 3rd party with relevant certifications, and keep records of wastes transfer including quantities?

All hazardous wastes such as waste oil rag were recycled by different 3rd qualified vendors, the transferring agreements were provided for review, the latest transfer record was on 15-May-2020.

Does factory inventory all waste water, including domestic waste water and industrial waste water, with sources and quantities?

The factory had not established inventory for waste water including industrial and domestic waste water with sources and quantities.

If applicable, is factory able to demonstrate that waste water is treated adequately before discharge, with relevant equipment and trained staff?

As per EIA requirements, the factory was not required to install a wastewater treatment plant, all the industrial wastewater was transferred to the qualified vendor, the transfer contract and manifest was provided for review during this audit.

Is factory able to demonstrate that waste water at discharge point is meeting the local standards requirement (through lab testing reports)?

No industrial waste water discharged by the factory.

When observing waste water discharge point, does water seem to have color or odor on audit day?

No industrial waste water discharged by the factory.

Does factory inventory all air emissions, with sources and identification of treatment needed?

The factory had not established the air emission inventory, with sources and identification of the treatment needed.

Is factory able to demonstrate that air quality at factory’s boundaries is meeting the local standards requirement (through lab testing reports)?

Based on lab testing report that all air emissions was met the local standard requirements (last testing report on 7-Jul-2020)

On audit day, is there any smell, fog, or dust observed by auditor on factory’s direct environment, linked to factory’s activity?

No smell, fog, or dust observed by auditor on factory’s direct environment.

Is factory able to demonstrate that noise level at factory’s boundaries is meeting the local standards requirement (through lab testing reports)?

Based on lab testing report that all boundaries noise level was met the local standard requirements (last testing report on 7-Jul-2020).

Can factory demonstrate that energy use is monitored and that actions have been taken to reduce energy use?

The factory had monitored energy use and takes some actions to reduce energy use. For example, shut down power switch timely.

Can factory demonstrate that water use is monitored and that actions have been taken to reduce water use?

The factory had monitored water use and takes some actions to reduce water use. For example, all workers should turn off the tap after using.

- Child Labour

Does the factory complies with the legal minimum age? Please note the age of the youngest worker found.

16 years old with restriction and the youngest employee is 18 years old in the factory who born on 12-May-2002 and hired on 27-Aug-2020.

Does the factory have effective procedures such as verifying suspected young worker documents to confirm the correct age of the worker at the time of recruitment?

The factory has established the procedure to verify the age of employees. Age document was checked together with the employee statement before recruitment.

Does the factory sign contracts with all workers and keep copies or records of ID documents of workers or similar way to check age?

The factory signs contracts with the workers and keeps copies or records of ID documents of workers to check age.

Does the factory understand the requirements of laws and regulations on child labour and young workers? If so, is there a written child labor policy?

The factory understands the requirements of laws and regulations on child labour and young workers. The procedure was also established.

Are young workers exempted from overtime?

No young worker was employed in the factory

Are young workers exempted from night shift?

No young worker was employed in the factor

Are young workers exempted from hazardous work?

No young worker was employed in the factory.

Are young workers registered and given annual health checks?

No young worker was employed in the factory.

- Hours, Wages & Benefit

Do the working hours of individual workers comply with local regulation? Do the working hours exceeds the international recommendation of 60 hours / week ?

Legal normal working hours: 8 hours/day, 40 hours/week Legal overtime hours: 3 hours/day, 36 hours/month Based on management interview and document review, the peak season in the factory was from June to September. Attendance records from 1-Oct-2019 to audit day were provided, of Sep, 2020 (current month), Jun, 2020 (peak month) and Dec, 2019 (low month) were taken as samples. The daily overtime working was detected for 10 sample employees in Sep, 2020 (current month), Jun, 2020 (peak month) and Dec, 2019 (low month), with the maximum daily overtime up to 3 hours, 3 hours, 3 hours respectively. The factory did not ensure overtime hours comply with legal requirements and weekly working hours within 60 hours/week. Based on review the attendance records from 1-Oct2019 to 26-Nov-2020 of the factory, the monthly overtime hours for all sampled workers exceeded 76-96 hours, the weekly working hours for all sampled workers exceeded 60 hours and up to 66 hours in Sep, 2020 (current month), the monthly overtime hours for all sampled workers 90-96 hours, the weekly working hours for all sampled workers exceeded 60 hours and up to 66 hours in Jun, 2020 (peak month), the monthly overtime hours for all sampled workers 75-99 hours, the weekly working hours for all sampled workers exceeded 60 hours and up to 66 hours in Dec, 2019 (low month)

Do workers have 1 day off within 7 days (or 2 days off within 14 days where applicable)?

Based on reviewing the provided attendance records from 1-Oct-2019 to the audit date, it was noted that all sampled workers could enjoy one day off in a week. The maximum consecutively working day was 6 days in the factory

Does the factory record the working hours of individual workers in a reliable manner?

The factory had electronic attendance system (fingerprinting system) to record the working hours.

Are workers given reasonable time for lunch and rest breaks?

The normal working hours in the factory were 8 hours per day 5 days per week. Workers from injection department were conducted for two shifts: 8:00-20:00 and 20:00-8:00 with 1 hour rest in each shift. All other workers were conducted for one shift, 8:00-12:00, 13:30-17:30, OT from 18:00 to 21:00 at most. Worker needed to work overtime on Saturdays, but never on Sundays.

Are workers assigned overtime on a voluntary basis?

As per the interviewed employees, overtime was conducted on a voluntary basis.

Do workers have legal vacation, national holidays and paid leave?

The employees can enjoy their legal vacation and national holiday.

Is there any evidence that the legal minimum wage is not paid for regular working hours ? Please specify

Local legal minimum wage was RMB 1720 per month which equivalent to RMB 9.89 per hour since 1-Jul2018. Per document review, 12 months’ payrolls records from Oct, 2019 to Sep, 2020, the minimum wage in the factory for workers was at least RMB 1800/month; which was above the local minimum wage requirements.

Are overtime hours paid with legal premium?

Overtime hours were paid with legal premium. 150% of normal wages for overtime on weekdays; 200% of normal wages for overtime on rest days; no overtime work on holidays.

Does the factory have written employment conditions on compensation, compensation methods and benefits that is communicated to and understood by all workers?

The factory has a clear written employment conditions on compensation, compensation methods and benefits that is communicated to and understood by all workers.

Is the payment paid at a reasonable and legal frequency (monthly), and in a form convenient for workers (cash, bank, …)?

The payrolls were calculated by hourly rate and paid before the end of the following month by bank transfer

Do workers receive a pay slip to sign that has information that will allow them to confirm their wages and see all deductions and bonuses?

Pay slip was provided to the employees before payment.

Are deductions fair, reasonable and legal (such as social insurance or other tax)?

Social insurance, housing fund, electric and water charge was deducted from wages, which was acceptable.

Is maternity and paid leaves paid as per regulations?

Maternity and paid leave are paid as per regulation

If deductions as disciplinary practices are used, are they falling under regulatory rules?

No disciplinary deduction as confirmed by workers

- Labor Practices

If applicable by Local Law, do workers have the right to join or for trade unions and bargain collectively, without interference of employer?

Workers had the right to join or for trade unions and bargain collectively, without interference of employer.

If there is no union, are there fair and effective parallel means to resolve grievances of workers (workers representatives,…)?

No trade union established, but 6 worker representatives were selected by the factory. And the employees were freely to join any union as they want. Suggestion box was also installed for the employees

Is there evidence that workers cannot efficiently communicate grievances to management out of direct supervisors?

The employees could use suggestion boxes to efficiently communicate grievances to senior management.

Is there evidence that work is conducted in voluntary basis, with no threat of penalty or sanctions, and the factory do not use forced, bonded or involuntary prison lab our?

Evidence showed that work is conducted in voluntary basis, with no threat of penalty or sanctions, and the factory do not use forced, bonded or involuntary prison lab our

Is there evidences that factory do not require workers to lodge deposits or original documents such as work permits/ID papers, cards, training certificates, etc.?

The factory did not require workers to lodge deposits or original documents such as work permits/ID papers, cards, training certificates, etc.

Are workers free to quit their jobs within the legal framework and without debts forcing them to continue working for the factory?

Workers were free to quit their jobs within the legal framework and without debts forcing them to continue working for the factory.

The factory doesn’t withhold any part of workers salary or benefits in order to force such worker to continue working for the factory?

The factory did not withhold any part of workers salary or benefits in order to force such worker to continue working for the factory.

Are workers allowed to leave the factory compound after work at any time and freely move about during a shift (attend to hygiene etc)? If not, please specify.

Workers were allowed to leave the factory compound after work at any time and freely move about during a shift.

Is non-discrimination guarantee in term of employment, promotion, compensation, welfare, dismissal and retirement, etc. within the company based on criteria of race, birth, religion, national or social origins, sex, family responsibilities, marital status, handicap, sexual orientation or political opinions?

No negative evidence of discrimination in gender was identified during the audit. And the discrimination procedure was available in the factory.

The factory doesn’t insist on blood tests, pregnancy or virginity tests before hiring?

The factory did not require blood tests, pregnancy or virginity tests before hiring.

Is there a written anti-discrimination policy?

There was a written anti-discrimination policy

Is mental / physical /sexual coercion forbidden and avoided in the factory? If not, please give details of the situation.

There was no mental / physical /sexual coercion forbidden and avoided in the factory.

Does the factory have documented disciplinary rules that are clearly communicated to all workers?

The factory documented disciplinary rules that was clearly communicated to all workers

Does the company keep a record of fines/disciplinary actions?

No fines/disciplinary actions were found in the factory.

Are the complaint and appeal methods defined and proved to be efficient?

The employees could use suggestion boxes and hotline to complaint and appeal methods, and the management would solve it every week.

In order to meet the market demand, Shanli Crafts also has many product test reports, such as MSDS LIQUID TEST REPORT, lead test, MICROBLOLOGY TEST, if you have other testing needs, please contact our business department directly.